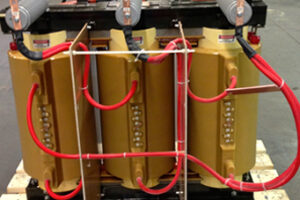

Epoxycast Coil Transformers

At AFP Transformers, our Epoxycast transformers provide several benefits to traditional dry type transformers. Epoxycast transformers can withstand high power surges as a result of higher BIL ratings. The coils are directly cast into the mold under pressure, instead of using vacuum pressure impregnation to apply resin to the coils. The coil is deeply embedded in the epoxy material, protecting coils from contaminates and holding the windings in place during power surges. The secondary coils are standard dry type processed with a polyester resin in VPI process.

Epoxy material is strong and requires little maintenance. As a dry type transformer, there are no hazardous liquids or materials to pose a safety risk. Since they do not contain hazardous materials, Epoxycast transformers do not require transformer vaults that limit placement options and significantly add to the cost of liquid transformers.

AFP Transformers manufactures a wide range of transformers from 600V to 34.5 kV voltage classes. Epoxycast transformes are used in a variety of application including control power transformers, pad-mount distribution transformers, and neutral grounding transformers used in utility and cubicle applications. For additional information about this product see the table below, or Contact Us directly.

5kV to 15kV Class EpoxyCast ITI Part Cross Reference Request a Quote

EpoxyCast Transformer Capabilities

- Transformer Type

- Control Power Transformers

- Neutral Grounding Transformers

- Distribution Transformers

- Power Transformers

- Features

- Non-flammable

- Superior Short Circuit Resistance

- Low/No Maintenance Required

- Leak Proof

- No Hazardous Materials

- Power Type

- Single Phase

- Three Phase

- Voltage Class

- 600 V

- 5 kV

- 15 kV

- 34.5 kV

- Construction

Cast Coil (Epoxycast®)

- Winding Material

- Copper Wire Standard

- Additional Configurations on Request

- BIL Rating

60kV to 200kV

Dependent on Transformer Voltage Rating

- Testing & Inspection

100% Product Testing

IEEE C57.12.91 Special, Standard, or Custom

Testing Parameters Stored- Voltage

- Current

- Watts

- Vars

- VA

- Power Factor

- Efficiency

Applied Potential (HiPot) Testing to 100 kV AC RMS

BIL capability up to 300 kV

Partial Discharge Testing- Up to 100 kV applied potential

- In excess of 70 kV induced potential

Customer Specified Testing as Requested

- Stocking Programs

- Kanban

- JIT Shipping

- Min-Max

- Custom

- Production Volume

- Prototype

- Low Volume

- High Volume

- Lead Time

- 3 to 6 Weeks Typical

- Expedited Turnaround in as little as 1 Week

Additional Information

- Industry Focus & Applications

Switchgear Manufacturers

Motor Control Center Manufacturers

Utilities

Power Factor Correcting Equipment Manufacturers

Power Conditioning Equipment Manufacturers- PDU manufacturers

- UPS manufacturers

- Voltage Regulator Manufacturers

- Data Center CPUs

Industrial Heating Equipment Manufacturers

- Furnaces

- Induction Heating Power Supplies

- RF and Microwave Heating Machines

Mining Machine Manufacturers

Waste Water Treatment

OEM Machine Manufacturers- Machine Toolmakers

- Packaging Machines

- Semiconductor Machine Manufacturers

- Web Processing Machine Manufacturers

- Industry Standards

IEEE C57.12.01

General Requirements for Dry-Type Distribution & Power Transformers, Including Solid Cast

IEEE C57.12.91

Standard Test Code for Dry-Type Distribution & Power Transformers

UL 508

UL Standard for Industrial Control Equipment

UL 506

UL Standard for Specialty Transformers

UL 1561

Industry Standard for Dry Type General Purpose & Power Transformers, 600 Volt Class

UL 1562

Industry Standard for Dry Type General Purpose & Power Transformers, Medium Voltage, Up to 34.5 KV

NEMA ST 20

Standard for Dry Type Transformers for General Applications

NEMA TR1

Test Code for Transformers, Regulators & Reactors

NEMA ICS 2

Industrial Standard for Controllers, Contactors, Overload Relays & Related Equipment. (Motor Starting Autotransformers & Reactors)International Standards

IEC 60076

Power Transformer & Reactors – Medium Voltage

IEC 61558

Power Transformers & Reactors – 600 Volt Class

CE Certification to IEC StandardsMarine Standards

ABS

American Bureau of Ships

DNV

Det Norske Veritas

Single Phase

| Below with + 7.5% and -7.5% Primary taps and 120v / 240v Secondaries | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Primary Voltage | 14,400 | 13,800 | 13,200 | 12,470 | 12,000 | 8,320 | 7,620 | 7,200 | 4,800 | 4,160 | 2,400 | Outline |

| BIL Rating | 95 kV | 95 kV | 95 kV | 95 kV | 95 kV | 95 kV | 95 kV | 95 kV | 60 kV | 60 kV | 60 kV | |

| 5 kVA | 410304 | 410306 | 410308 | 410310 | 410312 | 410314 | 410316 | 410318 | 410320 | 410322 | 410324 | EpoxtCast 5kVA 5_15kV Class 1Phase Master Outline |

| 10 kVA | 410404 | 410406 | 410408 | 410410 | 410412 | 410414 | 410416 | 410418 | 410420 | 410422 | 410424 | EpoxtCast 10kVA 5_15kV Class 1Phase Master Outline |

| 15 kVA | 410504 | 410506 | 410508 | 410510 | 410512 | 410514 | 410516 | 410518 | 410520 | 410522 | 410524 | EpoxtCast 15kVA 5_15kV Class 1Phase Master Outline |

| 25 kVA | 410604 | 410606 | 410608 | 410610 | 410612 | 410614 | 410616 | 410618 | 410620 | 410622 | 410624 | EpoxtCast 25kVA 5_15kV Class 1Phase Master Outline |

| 37.5 kVA | 410704 | 410706 | 410708 | 410710 | 410712 | 410714 | 410716 | 410718 | 410720 | 410722 | 410724 | EpoxtCast 37.5kVA 5_15kV Class 1Phase Master Outline |

| 50 kVA | 410804 | 410806 | 410808 | 410810 | 410812 | 410814 | 410816 | 410818 | 410820 | 410822 | 410824 | EpoxtCast 50kVA 5_15kV Class 1Phase Master Outline |

| 75 kVA | 410904 | 410906 | 410908 | 410910 | 410912 | 410914 | 410916 | 410918 | 410920 | 410922 | 410924 | EpoxtCast 75kVA 5_15kV Class 1Phase Master Outline |

| 100 kVA | 411004 | 411006 | 411008 | 411010 | 411012 | 411014 | 411016 | 411018 | 411020 | 411022 | 411024 | EpoxtCast 100kVA 5_15kV Class 1Phase Master Outline |

| Below with + 5%; +2.5% and -2.5%; -5% Primary taps and 120v / 240v Secondaries | ||||||||||||

| Primary Voltage | 14,400 | 13,800 | 13,200 | 12,470 | 12,000 | 8,320 | 7,620 | 7,200 | 4,800 | 4,160 | 2,400 | Outline |

| BIL Rating | 95 kV | 95 kV | 95 kV | 95 kV | 95 kV | 95 kV | 95 kV | 95 kV | 60 kV | 60 kV | 60 kV | |

| 5 kVA | 410305 | 410307 | 410309 | 410311 | 410313 | 410315 | 410317 | 410319 | 410321 | 410323 | 410325 | EpoxtCast 5kVA 5_15kV Class 1Phase Master Outline |

| 10 kVA | 410405 | 410407 | 410409 | 410411 | 410413 | 410415 | 410417 | 410419 | 410421 | 410423 | 410425 | EpoxtCast 10kVA 5_15kV Class 1Phase Master Outline |

| 15 kVA | 410505 | 410507 | 410509 | 410511 | 410513 | 410515 | 410517 | 410519 | 410521 | 410523 | 410525 | EpoxtCast 15kVA 5_15kV Class 1Phase Master Outline |

| 25 kVA | 410605 | 410607 | 410609 | 410611 | 410613 | 410615 | 410617 | 410619 | 410621 | 410623 | 410625 | EpoxtCast 25kVA 5_15kV Class 1Phase Master Outline |

| 37.5 kVA | 410705 | 410707 | 410709 | 410711 | 410713 | 410715 | 410717 | 410719 | 410721 | 410723 | 410725 | EpoxtCast 37.5kVA 5_15kV Class 1Phase Master Outline |

| 50 kVA | 410805 | 410807 | 410809 | 410811 | 410813 | 410815 | 410817 | 410819 | 410821 | 410823 | 410825 | EpoxtCast 50kVA 5_15kV Class 1Phase Master Outline |

| 75 kVA | 410905 | 410907 | 410909 | 410911 | 410913 | 410915 | 410917 | 410919 | 410921 | 410923 | 410925 | EpoxtCast 75kVA 5_15kV Class 1Phase Master Outline |

| 100 kVA | 411005 | 411007 | 411009 | 411011 | 411013 | 411015 | 411017 | 411019 | 411021 | 411023 | 411025 | EpoxtCast 100kVA 5_15kV Class 1Phase Master Outline |

Three Phase

| Above with + 7.5% and -7.5% Primary taps and 120v / 240v Secondaries | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Primary Voltage | 14,400 | 13,800 | 13,200 | 12,470 | 12,000 | 8,320 | 7,620 | 7,200 | 4,800 | 4,160 | 2,400 | Outline |

| BIL Rating | 95 kV | 95 kV | 95 kV | 95 kV | 95 kV | 95 kV | 95 kV | 95 kV | 60 kV | 60 kV | 60 kV | |

| 15 kVA | 460304 | 460306 | 460308 | 460310 | 460312 | 460314 | 460316 | 460318 | 460320 | 460322 | 460324 | EpoxtCast 15kVA 5_15kV Class 3Phase 208v Master Outline |

| 30 kVA | 460404 | 460406 | 460408 | 460460 | 460412 | 460414 | 460416 | 460418 | 460420 | 460422 | 460424 | EpoxtCast 30kVA 5_15kV Class 3Phase 208v Master Outline |

| 45 kVA | 460504 | 460506 | 460508 | 460510 | 460512 | 460514 | 460516 | 460518 | 460520 | 460522 | 460524 | EpoxtCast 45kVA 5_15kV Class 3Phase 208v Master Outline |

| 75 kVA | 460704 | 460706 | 460708 | 460710 | 460712 | 460714 | 460716 | 460718 | 460720 | 460722 | 460724 | EpoxtCast 75kVA 5_15kV Class 3Phase 208v Master Outline |

| 112.5 kVA | 460904 | 460906 | 460908 | 460910 | 460912 | 460914 | 460916 | 460918 | 460920 | 460922 | 460924 | Consult Sales for Outline |

| 150 kVA | 461004 | 461006 | 461008 | 461010 | 461012 | 461014 | 461016 | 461018 | 461020 | 461022 | 461024 | Consult Sales for Outline |

| 225 kVA | 461104 | 461106 | 461108 | 461110 | 461112 | 461114 | 461116 | 461118 | 461120 | 461122 | 461124 | Consult Sales for Outline |

| 500 kVA | 461304 | 461306 | 461308 | 461310 | 461312 | 461314 | 461316 | 461318 | 461320 | 461322 | 461324 | Consult Sales for Outline |

| Above with + 5%; +2.5% and -2.5%; -5% Primary taps and 120v / 240v Secondaries | ||||||||||||

| Primary Voltage | 14,400 | 13,800 | 13,200 | 12,470 | 12,000 | 8,320 | 7,620 | 7,200 | 4,800 | 4,160 | 2,400 | Outline |

| BIL Rating | 95 kV | 95 kV | 95 kV | 95 kV | 95 kV | 95 kV | 95 kV | 95 kV | 60 kV | 60 kV | 60 kV | |

| 15 kVA | 460305 | 460307 | 460309 | 460311 | 460313 | 460315 | 460317 | 460319 | 460321 | 460323 | 460325 | EpoxtCast 15kVA 5_15kV Class 3Phase 208v Master Outline |

| 30 kVA | 460405 | 460407 | 460409 | 460411 | 460413 | 460415 | 460417 | 460419 | 460421 | 460423 | 460425 | EpoxtCast 30kVA 5_15kV Class 3Phase 208v Master Outline |

| 45 kVA | 460505 | 460507 | 460509 | 460511 | 460513 | 460515 | 460517 | 460519 | 460521 | 460523 | 460525 | EpoxtCast 45kVA 5_15kV Class 3Phase 208v Master Outline |

| 75 kVA | 460705 | 460707 | 460709 | 460711 | 460713 | 460715 | 460717 | 460719 | 460721 | 460723 | 460725 | EpoxtCast 75kVA 5_15kV Class 3Phase 208v Master Outline |

| 112.5 kVA | 460905 | 460907 | 460909 | 460911 | 460913 | 460915 | 460917 | 460919 | 460921 | 460923 | 460925 | Consult Sales for Outline |

| 150 kVA | 461005 | 461007 | 461009 | 461011 | 461013 | 461015 | 461017 | 461019 | 461021 | 461023 | 461025 | Consult Sales for Outline |

| 225 kVA | 461105 | 461107 | 461109 | 461111 | 461113 | 461115 | 461117 | 461119 | 461121 | 461123 | 461125 | Consult Sales for Outline |

| 500 kVA | 461305 | 461307 | 461309 | 461311 | 461313 | 461315 | 461317 | 461319 | 461321 | 461323 | 461325 | Consult Sales for Outline |